Pioneering Sustainable Water Solutions

We combine engineering excellence with environmental stewardship to deliver state-of-the-art water treatment systems. From modular STPs to complex industrial ETPs, we ensure every drop counts.

Certified Quality

ISO 9001:2015 certified manufacturing and processes.

Eco-Friendly

Systems designed for low energy consumption and minimal footprint.

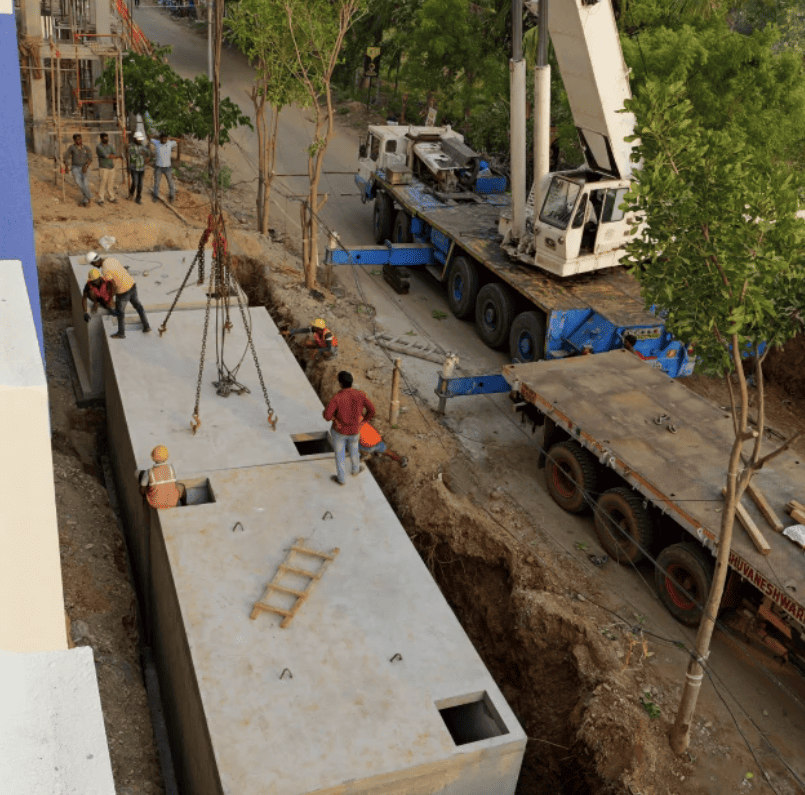

Our Precast RCC Tanks

Quality-engineered water storage solutions manufactured in our state-of-the-art facility.

Our Services

Comprehensive water management solutions tailored to your needs.

Our Projects

Discover how we've helped industries and communities manage water sustainably.

Our Process

A streamlined approach to delivering excellence.

Consultation

We start by deeply understanding your requirements and analyzing site conditions.

Design

Our experts engineer a custom solution optimized for efficiency and cost.

Installation

Seamless installation and rigorous testing to ensure peak performance.

Support

Ongoing 24/7 support to keep your systems running smoothly.

Client Testimonials

Hear what our satisfied clients have to say about our services.

Industries We Serve

Frequently Asked Questions

Find answers to common questions about our RCC precast tanks.

The excavation depth is finalized based on the selected tank model, invert levels of inlet/outlet pipes, and required cover above the tank. Your site engineer or Togreen Infra team will adjust the pit depth so that pipe slopes, traffic load requirements, and groundwater conditions are all safely met.

Each tank is supplied with a matching precast cover and seating detail, and the interface is filled with non‑shrink grout or mortar during installation. This creates a level, continuous bearing surface so the cover and walls act together and prevent gaps or leakage paths.

Togreen Infra tanks are provided with cast‑in lifting hooks or certified lifting points designed for safe handling. Standard crane slings, shackles, and spreader bars used by professional riggers are sufficient; no drilling or additional lifting holes should be made at site.

Battery tanks are linked using PVC/HDPE pipework through preprovided knockout zones or core‑cut openings at specified levels. Proper couplings, seals, and vent arrangements are used so that flow balance, venting, and maintenance access are maintained across all interconnected tanks.

Non‑shrink grout, PU sealant, or other approved elastomeric sealing compounds are recommended to fill the annular gap around the pipe. These materials bond well with concrete, accommodate minor movement, and prevent leakage or root ingress.

The main difference is the design load on the top slab and the required overburden cover. Medium‑duty covers are suitable for landscaped and pedestrian areas, while heavy‑duty covers are reinforced to carry vehicle loads such as cars, trucks, or fire tenders as specified.

Yes, vehicles can move over the tank only when a heavy‑duty tank and cover system has been specifically selected and installed with the required soil cover. For medium‑duty or non‑traffic tanks, vehicle movement must be restricted to avoid overstressing the slab.

Local bodies or pollution control boards may require approvals for sewage, STP, or ETP tanks, while water tanks usually follow buildingplan approvals. Togreen Infra can support with standard drawings and technical data so that consultants and clients can obtain the necessary permissions.

Our precast tanks can be installed below ground in open areas, driveways, parking zones, or landscaped spaces, provided there is proper access for excavation and lifting equipment. They can also be used in non‑traffic areas with lighter cover slabs where vehicles are not expected to pass.

Once the tank is installed, connected, and backfilled, it is not meant to be relocated. Any shifting would require re‑excavation and professional handling; therefore, the final position should be frozen before installation begins.

Yes, internal surfaces are treated in the factory with a cementitious polymer coating suitable for potable‑water or sewage applications, depending on the tank type. For drinking‑water tanks, only approved, nontoxic coatings are used and these are compatible with IS standards for potable water.

Where openings are not already provided, core cutting with suitable concrete drills is used to form precise holes without damaging reinforcement. Pipes are then inserted and sealed with non‑shrink grout and flexible sealant to keep the joint watertight.

Tanks are designed as liquid‑retaining structures as per relevant IS codes and undergo quality checks for dimensions, surface finish, and visible cracks. If required by the project, a site waterfill test can be carried out after installation to confirm watertightness before backfilling or final commissioning.

A mediumduty cover is engineered for non‑traffic or light‑traffic zones with lower wheel loads. A heavyduty cover is designed considering higher wheel loads, impact factors, and safety factors as per applicable IRC/IS codes, making it suitable for driveways and fire‑tender access routes.

Yes, like any water or sewage storage system, periodic cleaning and inspection are essential for hygiene and performance. The cleaning interval depends on usage and application, but manhole openings and internal layouts are designed to allow easy access for desilting and washing.

Precast tanks are factory‑made under controlled conditions, giving better quality, faster installation, and predictable performance compared to conventional cast‑in‑situ tanks. They minimise site labour, curing time, and leakage risk, and allow easy modular expansion by adding more units in the future.

Ready to Build Sustainable Infrastructure?

Partner with Togreen Infra for reliable precast and water treatment solutions.

Get in Touch