Choosing the right water treatment solution is crucial for ensuring water quality, regulatory compliance, and cost efficiency. Whether you're managing a residential complex, commercial building, or industrial facility, understanding your options helps you make informed decisions. This guide covers the key factors to consider when selecting between STP, ETP, and RO systems.

Understanding Your Water Treatment Needs

Before selecting a water treatment system, you need to understand the type and source of water you're dealing with:

- Domestic Wastewater: Generated from toilets, kitchens, and bathrooms in residential or commercial buildings

- Industrial Effluent: Wastewater from manufacturing, processing, or industrial operations

- Raw Water Purification: Groundwater, borewell, or municipal water requiring purification for drinking or process use

STP: Sewage Treatment Plant

STPs are designed specifically for treating domestic wastewater. They use biological processes to break down organic matter and remove contaminants.

Best For

- Residential apartments and housing societies

- Hotels and hospitality establishments

- Hospitals and healthcare facilities

- Commercial complexes and shopping malls

- Educational institutions

Key Technologies: SBR (Sequencing Batch Reactor), MBBR (Moving Bed Biofilm Reactor), MBR (Membrane Bio-Reactor)

Output: Treated water suitable for gardening, flushing, and non-potable reuse

Capacity Range: 10 KLD to 500+ KLD

ETP: Effluent Treatment Plant

ETPs handle industrial wastewater that contains chemicals, heavy metals, oils, dyes, and other industrial pollutants that require specialized treatment processes.

Best For

- Textile and dyeing industries

- Pharmaceutical manufacturing

- Chemical processing plants

- Food and beverage production

- Automotive and metal processing

- Dairy and meat processing

Key Processes: Chemical treatment, coagulation, flocculation, biological treatment, filtration

Output: Treated water meeting CPCB/SPCB discharge standards or suitable for industrial reuse

Capacity Range: 10 KLD to 1000+ KLD

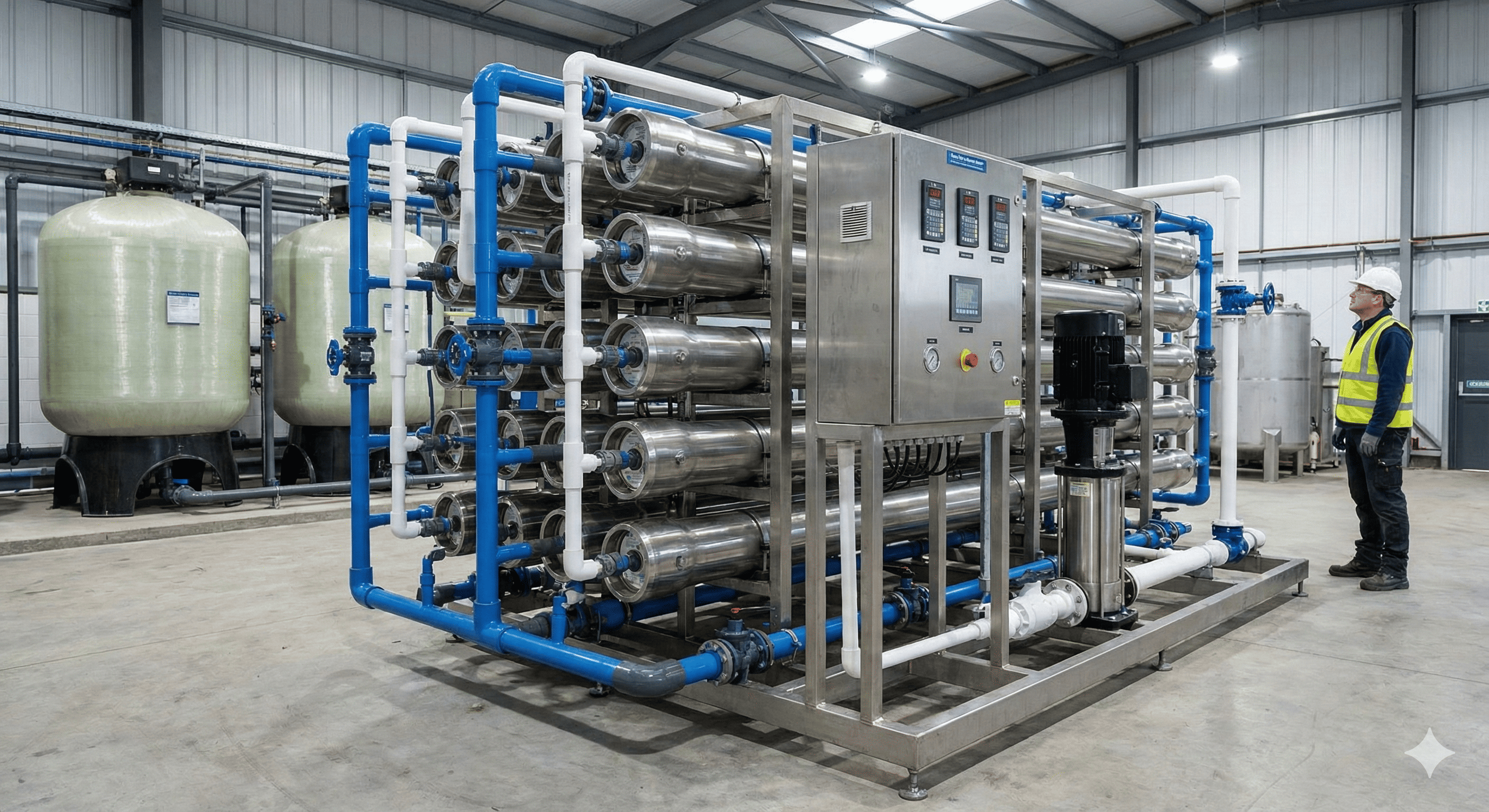

RO Plant: Reverse Osmosis

RO plants use membrane technology to purify water by removing dissolved salts, bacteria, and contaminants. They're used for producing pure drinking water or process water.

Best For

- Drinking water purification

- Packaged drinking water production

- Pharmaceutical process water

- Boiler feed water treatment

- High TDS groundwater treatment

- Brackish and seawater desalination

Technology: Semi-permeable membrane filtration under pressure

Output: Ultra-pure water meeting WHO/BIS drinking water standards

Capacity Range: 100 LPH to 100,000 LPH

Key Factors in Choosing Your System

1. Wastewater Characteristics

Analyze your water source for BOD, COD, TDS, pH, suspended solids, and specific contaminants. This determines whether you need STP, ETP, or a combination.

2. Regulatory Requirements

Understand CPCB/SPCB discharge norms applicable to your industry and location. Different standards apply to residential vs. industrial applications.

3. Space Availability

Modular and precast RCC systems from Togreen Infra require significantly less space than conventional civil construction, making them ideal for constrained sites.

4. Budget Considerations

Consider both capital expenditure (CAPEX) and operational costs (OPEX). Modular systems often offer lower total cost of ownership.

5. Future Expansion

Choose scalable solutions that can grow with your needs. Modular systems allow easy capacity expansion by adding units.

6. Reuse Potential

Determine if you want to reuse treated water and for what purpose—this influences the treatment level required.

Why Choose Togreen Infra?

At Togreen Infra, we provide customized water treatment solutions tailored to your specific needs:

- Expert Consultation: Free site assessment and water analysis

- Modular Design: Precast RCC systems for rapid deployment

- Complete Range: STP, ETP, and RO solutions under one roof

- Compliance Assured: All systems designed to meet CPCB/SPCB norms

- End-to-End Service: Design, installation, commissioning, and AMC

Not sure which system is right for you? Our technical team can conduct a thorough assessment of your requirements and recommend the most cost-effective and efficient solution. Contact us today for a free consultation.