Effluent Treatment Plant (ETP)

Industrial Wastewater Treatment Solutions

Where Industrial Effluent Comes From

Industrial wastewater is generated across many sectors, including textiles, pharmaceuticals, chemical processing, tanneries, food and dairy units, laundries, engineering units, and more.

These effluents often contain colour, organic load, chemicals, oils, and suspended solids that must be treated before discharge or reuse.

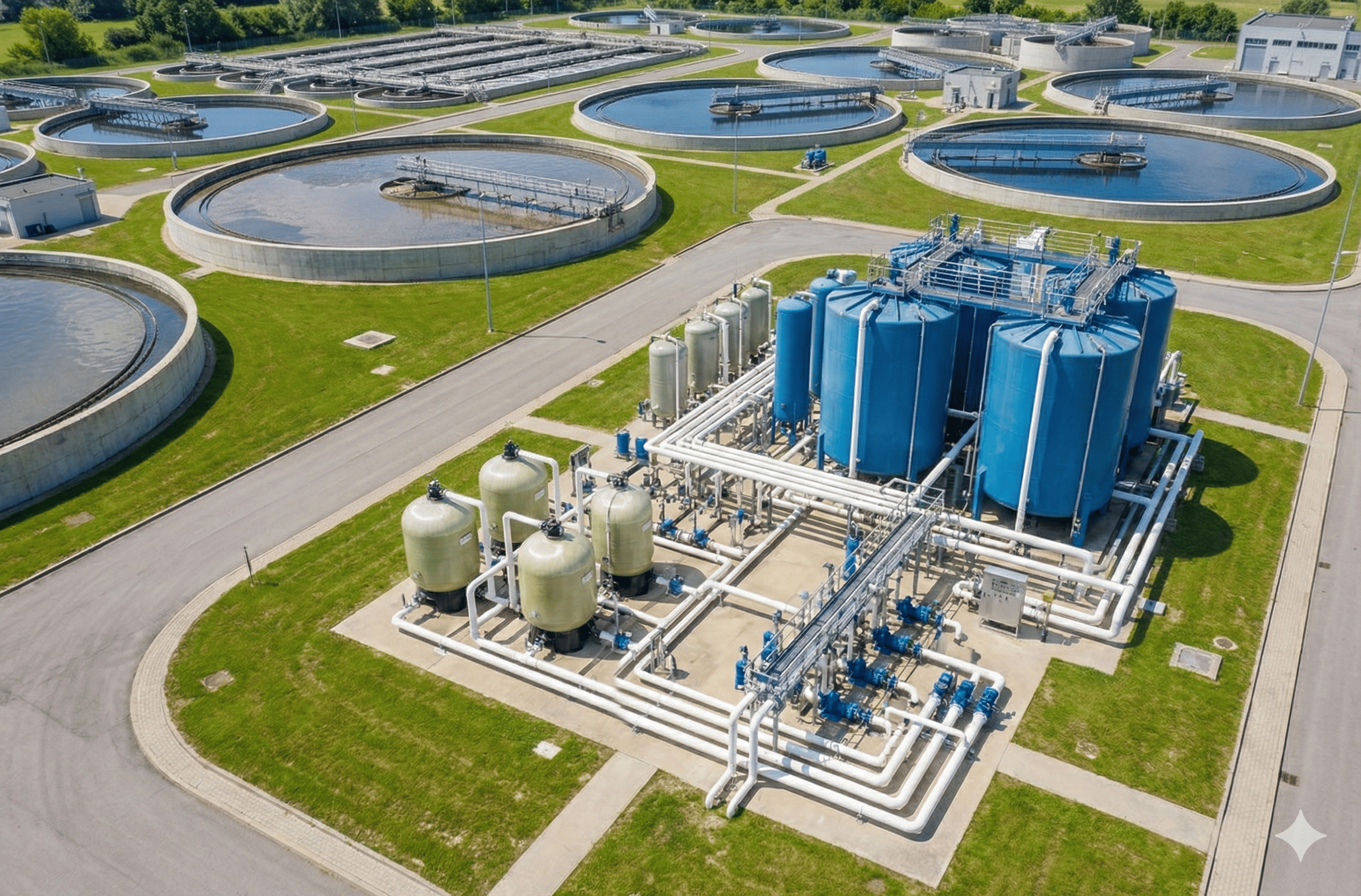

Effluent Treatment Plants (ETPs) installed by Togreen Infra Private Limited are designed to remove high levels of organic matter, solids, oils, heavy metals, and other pollutants from industrial wastewater. Using a combination of physical, chemical, and biological processes, these systems make the treated water safe for discharge or suitable for non‑potable reuse, depending on client requirements.

Why Effluent Treatment Is Essential

Protecting environment and ensuring regulatory compliance

Environmental Protection

Contaminated water cannot be released directly into the environment because it may contain toxic and non‑toxic substances harmful to people, soil, and aquatic life.

Water Source Protection

If left untreated, this wastewater can pollute surface and groundwater sources, damage ecosystems, and violate statutory pollution control norms.

Regulatory Compliance

Industries must comply with CPCB and SPCB statutory pollution control norms to operate legally and avoid penalties.

ETP Process Sequence at Togreen Infra

The typical process train in a Togreen Infra modular ETP

Inlet Screen Chamber

Initial solids removal and screening

Collection / Equalization Tank

Flow balancing and load equalization

Flash Mixer & Chemical Dosing

Rapid mixing with treatment chemicals

Clarifier / Clariflocculator

Sedimentation and flocculation

Aeration / Biological Treatment

Organic matter degradation (where applicable)

Secondary Clarifier

Final solids separation

Sludge Handling

Thickening and dewatering

Sludge Drying

Drying beds or mechanical dewatering

This engineered sequence ensures stable operation, consistent effluent quality, and compliance with CPCB/SPCB discharge standards for a wide range of industrial applications.

ETP Process Overview

Effluent treatment with Togreen Infra is a multi-stage operation

Preliminary Stage

Large solids removal, oil and grease interception via inlet screens and chambers.

Primary Stage

Sedimentation, chemical coagulation & flocculation in equalization tanks and clarifiers.

Secondary Stage

Organic matter degradation using bacteria, aeration tanks, or MBBR systems.

Tertiary Stage

Advanced filtration, UV or RO, ensuring legal discharge standards.

Recommended ETP Capacity by Industry

Customized solutions for different industry requirements

Textile & Garments

50–500 KLD

Dyeing, printing, and finishing effluent treatment

Pharmaceuticals

10–250 KLD

API manufacturing and formulation plants

Chemical Plants

100–1000 KLD

Specialty chemicals and petrochemicals

Dairy/Meat Processing

20–300 KLD

Food processing facility effluent

Food Processing

50–200 KLD

Beverages and packaged food units

Ready Mix Concrete

15–100 KLD

RMC plant wastewater treatment

CPCB Compliance Essentials

Central Pollution Control Board discharge standards we adhere to

Discharge Standards

- BOD: ≤ 30 mg/l

- COD: ≤ 250 mg/l

- TSS: ≤ 100 mg/l

- Oil & Grease: ≤ 10 mg/l

- pH range: 5.5–9.0

Our Approach

- Advanced automation with sensor-driven process control

- Online water quality monitoring and data logging

- Regulatory reporting and compliance support

- Remote technical diagnostics

ETP Costing (Indicative INR Ranges)

Estimated costs contingent on plant design, size, and treatment level

10–50 KLD

₹15–35 Lakhs

Small-scale industrial units

50–100 KLD

₹35–80 Lakhs

Medium-sized facilities

100–250 KLD

₹70L–2.0 Crores

Large industrial plants

250–500 KLD

₹1.5–5.0 Crores

Major manufacturing units

Factors Influencing ETP Pricing: Choice of civil vs. precast RCC structure, PLC/SCADA automation integration, type of secondary and tertiary processing modules, project site variables including terrain, accessibility, space, and logistics.

Project Delivery & Installation Schedule

Togreen Infra ensures one of the shortest timelines for ETP projects across the industry

Precast RCC Modular

Factory-made quality, rapid deployment, minimal site disruption

Civil-Based Traditional

Conventional construction with longer curing and setup time

Our advanced precast RCC technology enables up to 80% faster project completion compared to conventional civil builds, completing even large installations in record time.

Why Select Togreen Infra for Your ETP Project?

Top-tier effluent treatment solutions across India

Pan-India Presence

Active projects in Karnataka, Delhi, Maharashtra, Tamil Nadu, and Gujarat

Tailored Solutions

Custom designs for unique site requirements and complex industry standards

Precast RCC Tanks

Engineered for rapid, plug-and-play plant setup

IoT Enabled

Integrated dashboards for compliance and real-time plant performance

100% Compliance

CPCB discharge standard compliance assurance

Dedicated Support

After-sales AMC and customer support for every project

Frequently Asked Questions

ETP Solutions by Togreen Infra Private Limited

Yes. With advanced tertiary treatment processes such as UV disinfection, pressure filtration, and Reverse Osmosis (RO), treated water from a Togreen Effluent Treatment Plant (ETP) can be safely reused for gardening, flushing, cooling towers, boiler feed, and industrial process water, helping industries reduce freshwater dependency and operating costs.

With proper operation and scheduled maintenance, Togreen Infra's ETP systems are engineered to last 15–20 years or more. High-quality materials, robust mechanical design, and preventive maintenance ensure long-term durability and consistent performance.

Yes. Togreen provides customized and modular ETP designs capable of treating a wide range of industrial effluents. Our technical team conducts a detailed effluent analysis including BOD, COD, TDS, pH, oil & grease, heavy metals, and chemicals, and designs the most efficient and CPCB-compliant treatment solution.

Regular monitoring and preventive maintenance are essential for optimal ETP performance. Togreen Infra offers quarterly preventive maintenance schedules and ETP Annual Maintenance Contracts (AMC), which include routine system audits, spare parts inspection & replacement, process optimization, and technical troubleshooting & support.

Yes. Togreen's ETP systems can be integrated with IoT-based remote monitoring solutions. These platforms provide real-time operational data such as flow rate, BOD/COD trends, compliance logs, alarms, and performance alerts, ensuring uninterrupted regulatory compliance and operational efficiency.

Yes. All Togreen Effluent Treatment Plants are designed to meet CPCB and respective State Pollution Control Board (SPCB) discharge standards. We provide treated water test reports, process documentation, and compliance support for statutory approvals and audits.

Togreen Infra Private Limited is a trusted ETP manufacturer and EPC service provider in India, offering customized industrial ETP solutions, advanced primary/secondary/tertiary treatment, long equipment life & low operating cost, CPCB/SPCB-compliant treated water, and end-to-end ETP design, installation & AMC services.

Industries We Serve

Pharmaceutical & Biotech

ETP for pharmaceutical and biotech industries

Food Processing

ETP for food processing facilities

Oil Refineries

ETP for oil refineries & petrochemical units

Chemical Plants

ETP for chemical manufacturing plants

Automotive

ETP for automotive & metal processing workshops

Beverage & Dairy

ETP for beverage and dairy producers

Need an Industrial ETP Solution?

Seeking an economical and reliable ETP for your facility? Togreen Infra specializes in both custom-engineered and plug-and-play ETPs to suit your specific needs.

Get a Quote